Pharmaceutical Visual Inspection Machine

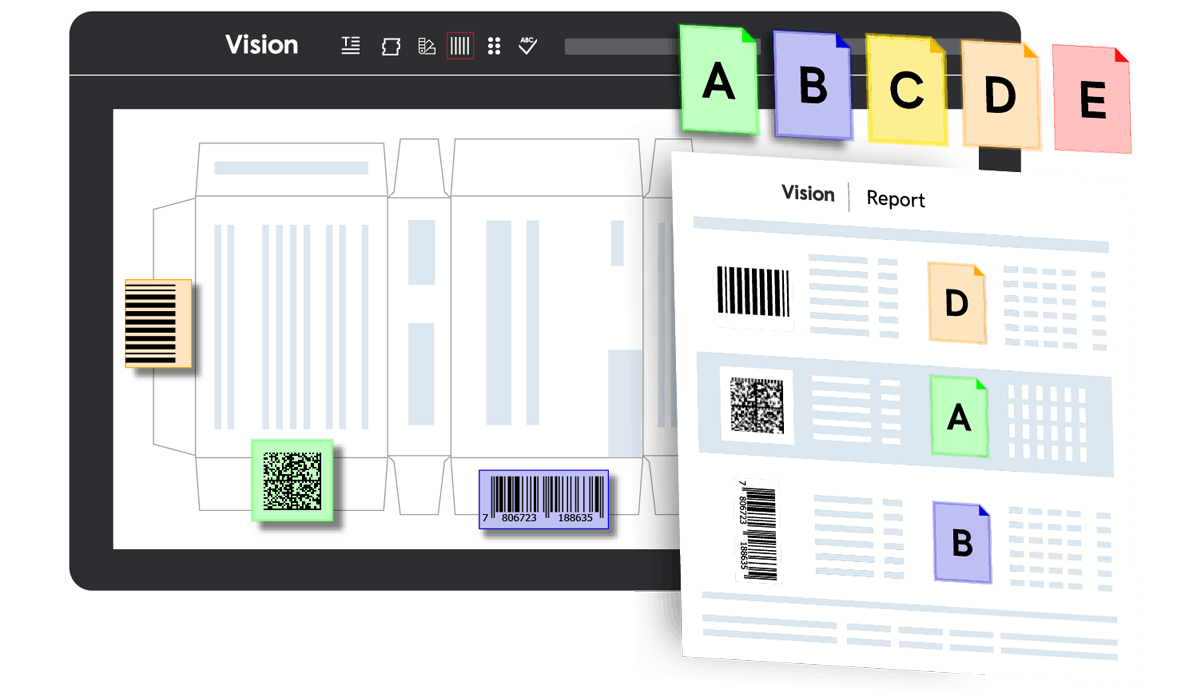

Comprehensive Defect DetectionIn pharmaceutical manufacturing, packaging plays a critical role in product safety, regulatory compliance, and operational efficiency. Barcode and QR code vision inspection systems leverage cutting-edge imaging and software technologies to ensure these essential identifiers are correctly printed, readable, and compliant with industry standards.

Technological Foundation of Barcode & QR Code Vision Inspection

Enhanced Compliance and Risk Mitigation

Ensuring drug safety, compliance, and traceability, visual barcode and QR code inspection systems technologies have become essential in pharmaceutical packaging for tracking, identification, anti-counterfeiting, and regulatory compliance. These essential identifiers are correctly printed, legible, and compliant with industry standards.

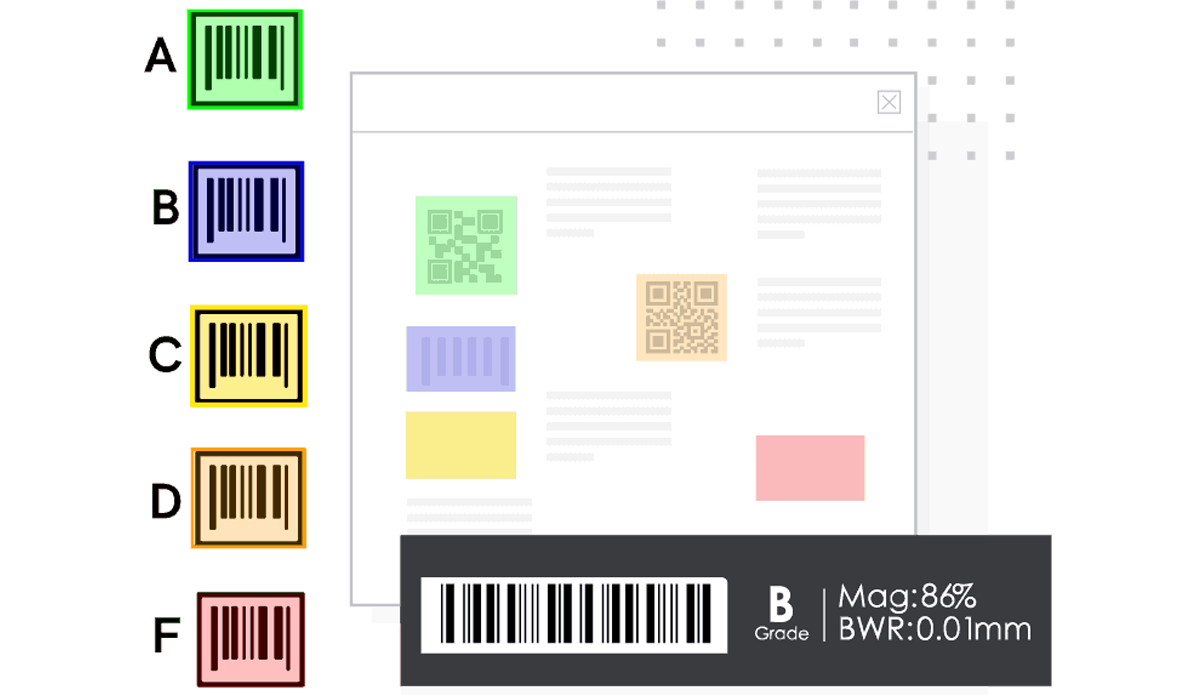

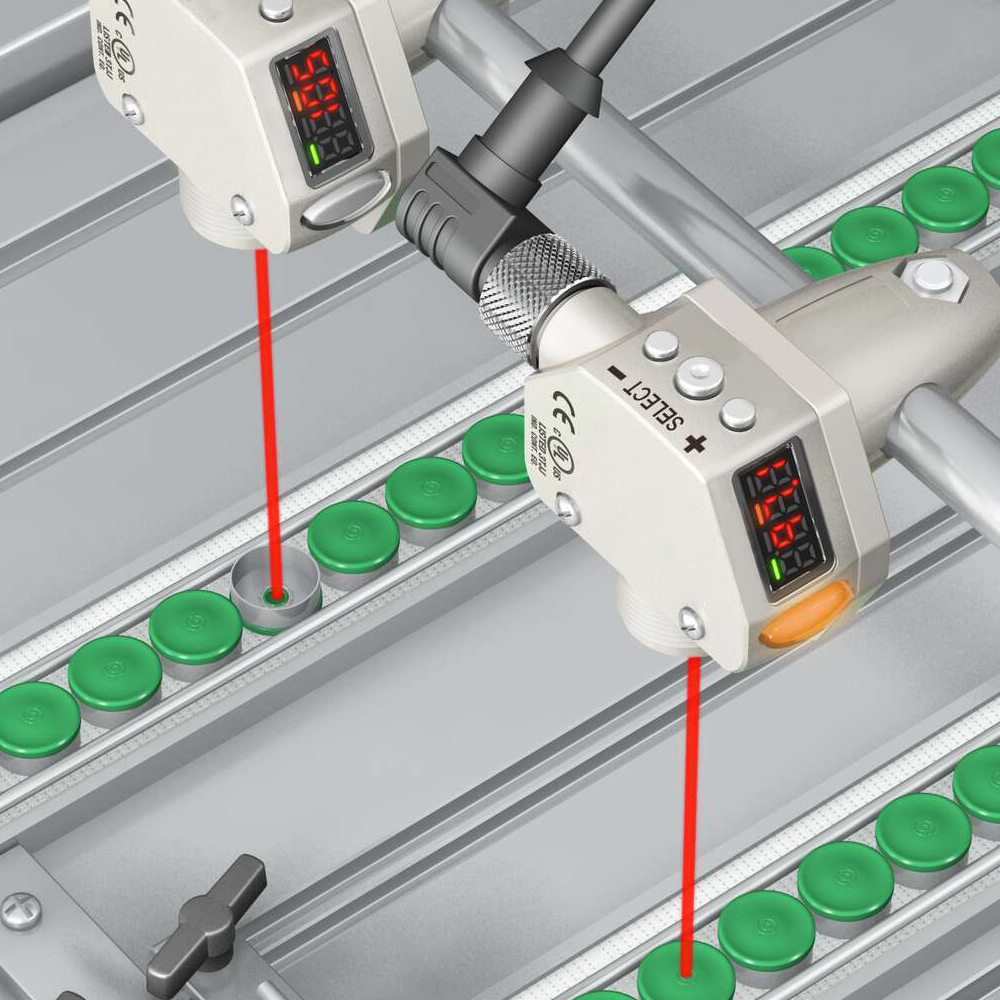

Accurate edge detection algorithmsMachine visual inspection system employs advanced image processing with edge detection to precisely identify barcode/QR boundaries on irregular surfaces, coupled with noise reduction algorithms to compensate for print defects and lighting variations, ensuring reliable decoding under challenging conditions.

Data Decoding & error correction algorithmsVisual inspection system system utilizes OCR technology to decode barcodes (interpreting bar/space patterns) and QR codes (analyzing 2D matrices) to interpret the 2D data patterns and translate them into readable information, incorporating error correction algorithms like Reed-Solomon to reconstruct damaged or distorted codes - crucial for maintaining readability despite packaging wear, scratches or smudges.

Machine Learning and AI-Based ValidationModern vision inspection systems now incorporate machine learning (AI/ML) to enhance traditional image processing, enabling continuous improvement through learned experience. Self-optimization capability allows them to automatically adapt to specific production environments by learning from historical inspection data, thereby increasing efficiency and reducing manual intervention requirements.

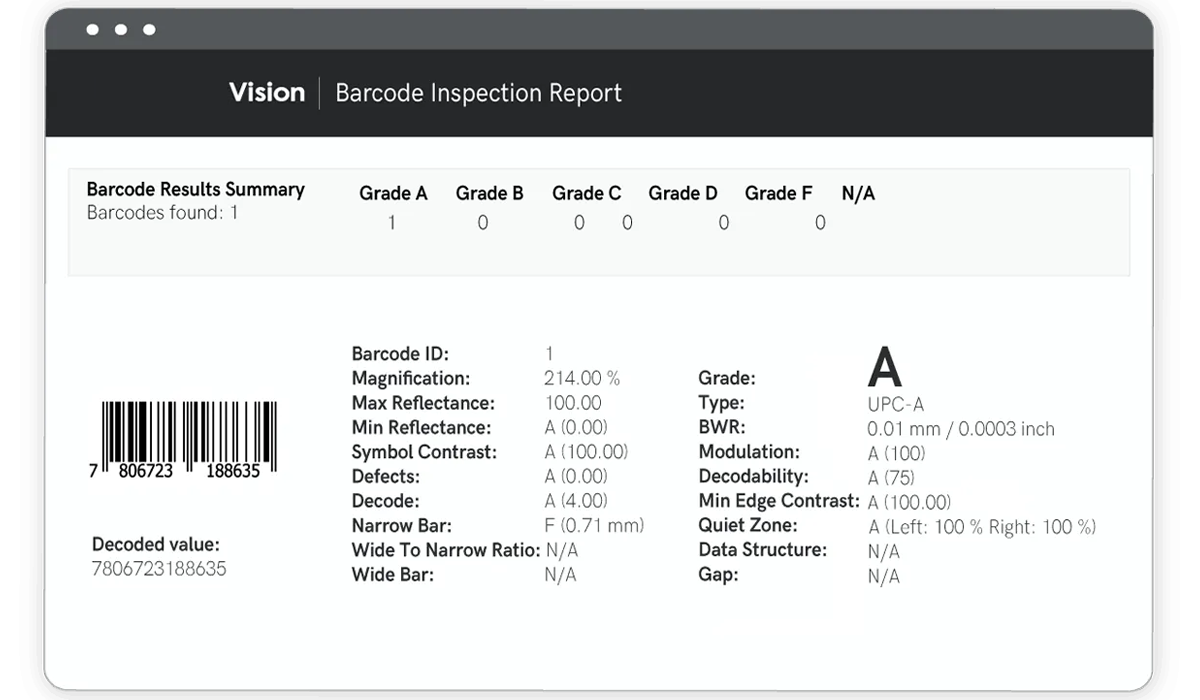

Symbol Quality Evaluation & ISO ComplianceVision inspection equipment rigorously evaluates barcode and QR code quality in full compliance with ISO/IEC 15416 (1D) and ISO/IEC 18004 (2D) international standards by analyzing critical parameters including contrast and brightness for optimal readability, verifying quiet zone integrity through size and cleanliness inspection, and assessing print quality by checking resolution while detecting any artifacts or distortion.

Empowering Pharmaceutical Production Line

Vision Inspection Technology

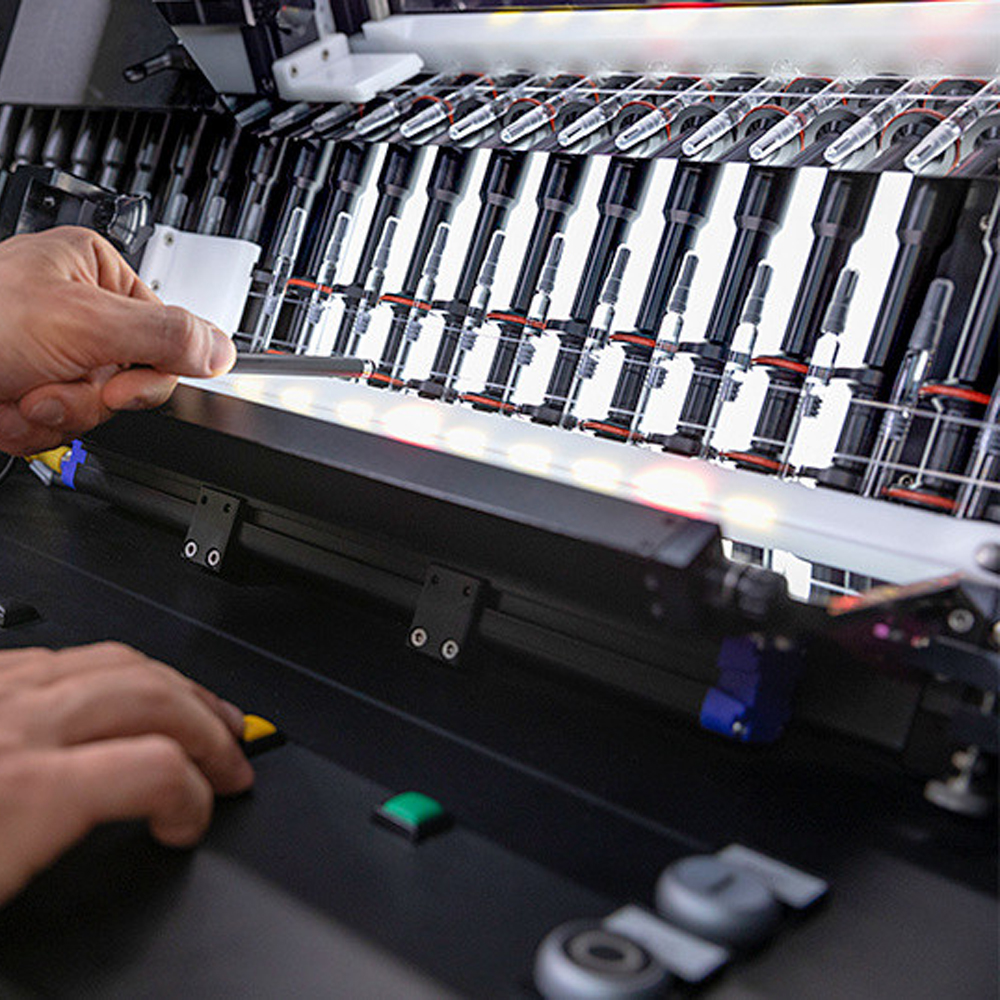

Investing in vision inspection technology not only enhances operational efficiency but also mitigates risks associated with counterfeit drugs, costly recalls, and regulatory non-compliance. With seamless integration into your existing systems and scalable capabilities, we empower your production line to perform with precision and confidence.

Enhancing Compliance and Efficiency

By integrating our vision inspection solutions into your production process, you not only ensure that your products are compliant and traceable, but you also improve the overall efficiency, reliability, and scalability of your packaging operations.

Histom Automated Bottle Neck D

Histom Automated Bottle Neck D

Automated Cap Color Consistenc

Automated Cap Color Consistenc

Auto Medicine Carton Box Damag

Auto Medicine Carton Box Damag

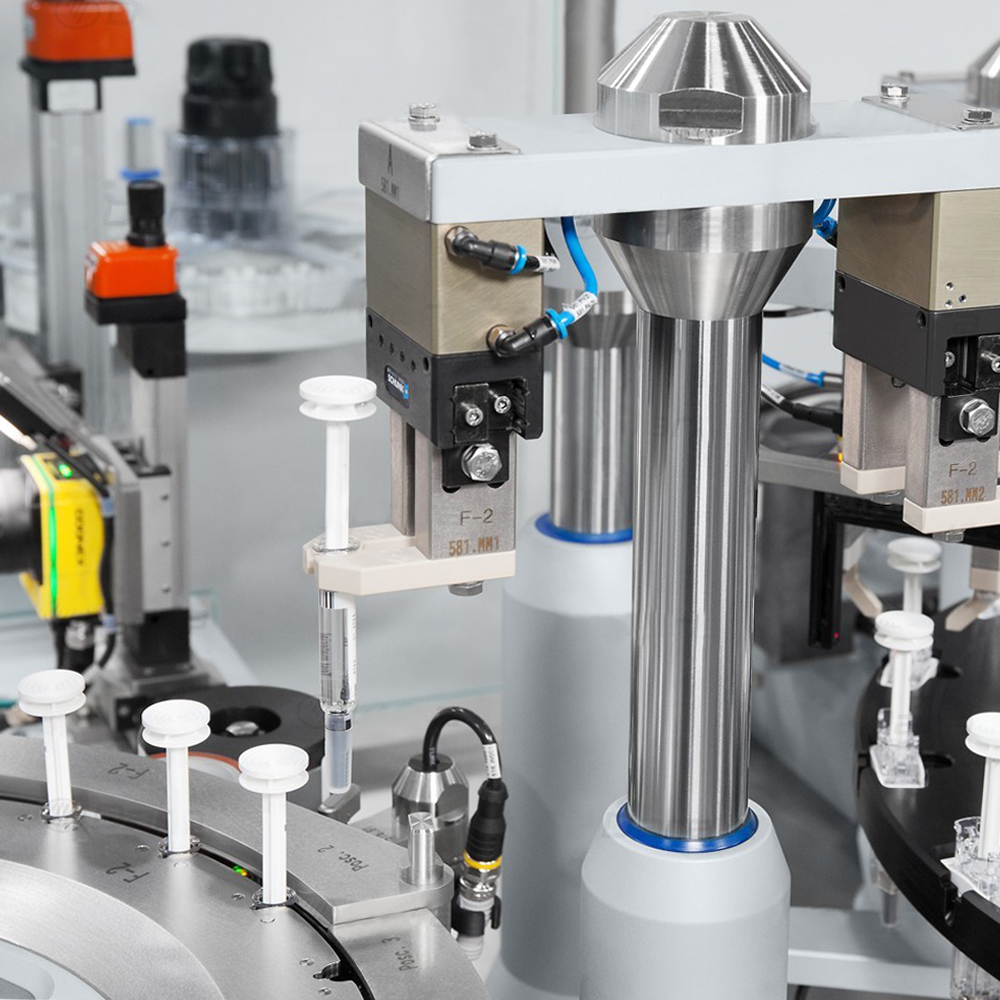

Syringe Scale Line Verificatio

Syringe Scale Line Verificatio